Bag in Box Manufacturer

Wholesale Custom Bag in Box Packaging

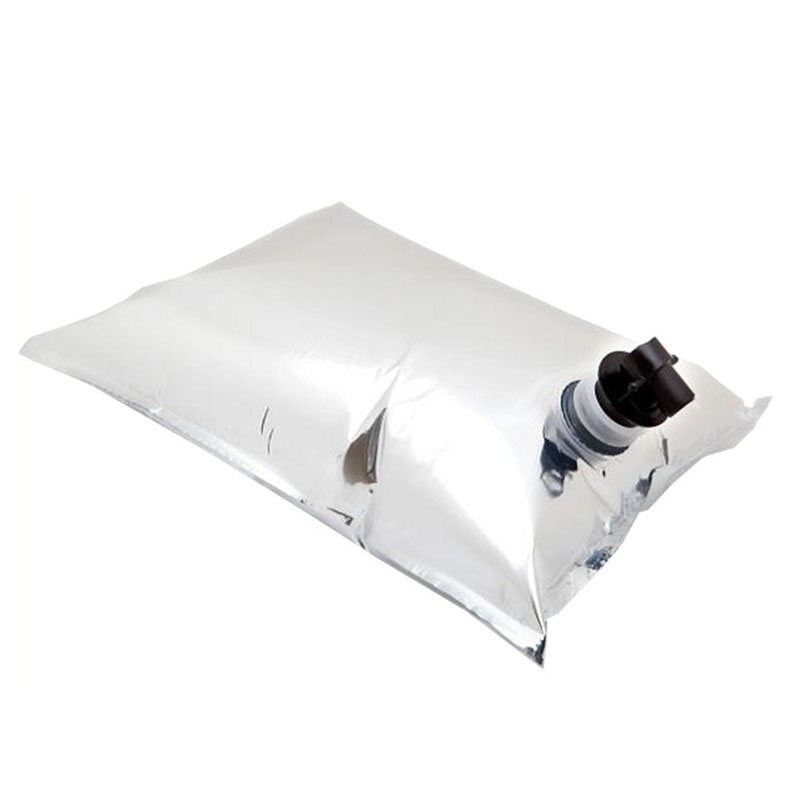

Bag in Box packaging is a modern liquid packaging solution combining a durable inner bag with an outer corrugated carton. It protects liquids from oxygen and light, extends shelf life, reduces waste, and is more economical and eco-friendly than traditional bottles.

Hot Bag in Box

Bag in Box Types

Bag in Box packaging comes in multiple styles, designed for different industries and liquid handling requirements.

- Standard Bag in Box with Tap

- Aseptic Bag in Box

- Wine Bag in Box

- Juice Bag in Box

- Dairy Bag in Box

- Oil Bag in Box

- Dispensing Bag in Box for Foodservice

- Coffee Concentrate Bag in Box

- Syrup Bag in Box

- Eco-Friendly Recyclable Bag in Box

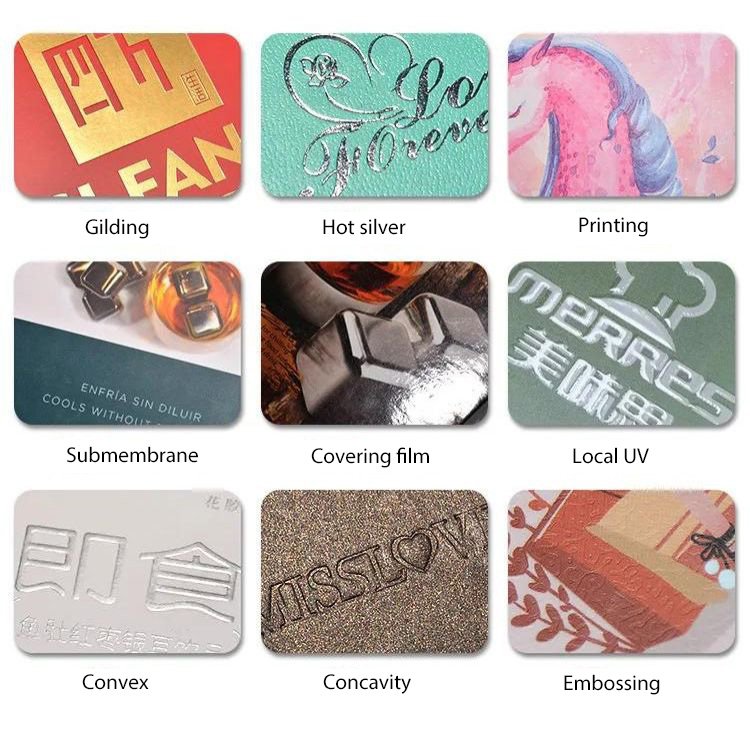

Bag in Box Customization

Bag in Box solutions can be fully customized to match your product’s functionality and branding.

From 1L to 25L for retail or bulk applications.

Options include PE, EVOH, metalized film for oxygen/light barrier.

High-quality offset or flexo printing on cartons.

Vitop, QCD, and custom dispensing systems.

Still not find what you're looking for? Contact our consultants for more available products.

How to Customize Bag in Box

Step 1: Consultation

Provide details about your liquid product and shelf-life requirements. We recommend the right Bag in Box structure.

Step 2: Design

Customize both the inner bag and outer carton with branding. We prepare mockups for approval.

Step 3: Manufacturing

High-speed machines produce sterile bags and strong cartons. All bags are tested for sealing and leakage.

Step 4: Delivery

Bag in Box sets are packed flat for cost-efficient shipping and delivered globally with reliable logistics support.

Bag in Box Manufacturing

Bag in Box production requires precision to ensure safety and functionality for liquids.

- Film Extrusion & Lamination – Multi-layer films with oxygen/light barriers.

- Bag Forming – Automated sealing of films into leak-proof bags.

- Spout & Tap Insertion – Secure fitments for easy and hygienic dispensing.

- Carton Production – Strong corrugated cartons printed and die-cut for outer protection.

Value-added Services

Our Bag in Box services go beyond standard production, helping you succeed in competitive markets.

Custom Dispensing Systems

Tailored taps and connectors for your product use.

Storage & Logistics Support

Flat-packed delivery to reduce storage space and costs.

Eco-Friendly Solutions

Fully recyclable or biodegradable bag and box options.

Technical Guidance

Assistance with filling machine compatibility and shelf-life testing.

What our happy customers say

Customer reviews are always the best reflection of our products and services. Take a look at what our customers have said.

“GreenWing’s Bag in Box packaging transformed our wine sales. Customers love the freshness, and we reduced shipping costs significantly.”

Laura Chen

Supply Chain Manager

“The Bag in Box solution for our fruit concentrates is hygienic, durable, and easy to dispense. GreenWing delivered on time with excellent service.”

Daniel Brooks

Operations Director

“We needed chemical packaging that was strong yet sustainable. GreenWing’s Bag in Box gave us the perfect balance of safety and eco-friendliness.”

Hiroshi Tanaka

CEO

Frequently Asked Questions

Q: What sizes are available for Bag in Box packaging?

A: We offer sizes from 1L to 25L, suitable for both retail and bulk distribution.

Q: Are the bags safe for food and beverage products?

A: Yes, all materials are BPA-free, FDA-approved, and certified for food contact.

Q: Can the Bag in Box be used for hot-fill products?

A: Yes, with special film structures, they can handle hot-fill and aseptic applications.

Q: How is the outer carton customized?

A: We provide offset/flexo printing, matte/gloss finishes, and full branding options.

Q: Is Bag in Box eco-friendly?

A: It uses less plastic than bottles, is recyclable, and reduces carbon footprint in transport.

Q: What is the lead time for production?

A: Standard lead time is 15–25 days depending on order quantity and customization.