Pouch With Tap Manufacturer

Customized Pouch With Tap Wholesale

Pouches with Tap offer secure, mess-free dispensing for liquids and semi-liquids in a lightweight, space-saving format. They outperform rigid containers in transport cost, shelf space, and user convenience—ideal for high-volume liquid packaging.

Hot Pouch With Tap

Pouch With Tap Types

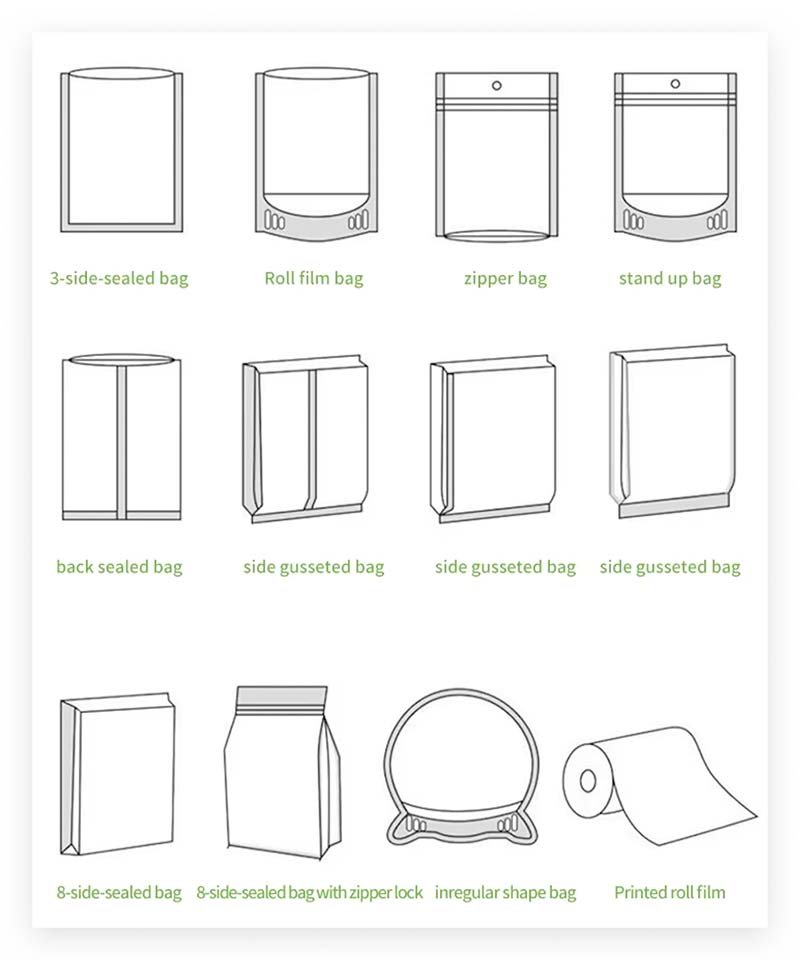

Tap pouches come in a variety of structures and film types to meet industrial and food-grade dispensing needs.

- Wine Tap Pouch

- Juice Tap Pouch

- Refill Cleaning Product Pouch

- BIB (Bag-in-Box) Pouch with Tap

- Kraft Paper Tap Pouch

- Foil Barrier Tap Pouch

- Clear View Tap Pouch

- Handle-Equipped Tap Pouch

- Large Capacity Tap Pouch (2L–10L)

- Custom-Shaped Tap Pouch

Pouch With Tap Customization

Create a pouch tailored for volume dispensing, safe transport, and maximum usability.

Available from 1L to 10L+ with reinforced structures for liquid weight.

Foil, PET, or multilayer films to block light, air, and maintain product freshness.

Front or bottom tap placement with push, twist, or pull-lock options.

Add die-cut or molded handles, custom shapes, or box compatibility for display.

Still not find what you're looking for? Contact our consultants for more available products.

How to Customize Pouch With Tap

Step 1: Consultation

Tell us your product volume and dispensing needs—we’ll recommend the best tap structure, film, and pouch format.

Step 2: Design

We create technical layouts and tap positioning mockups to match filling line compatibility and branding.

Step 3: Manufacturing

Lamination, printing, and precision sealing begin after approval. Taps are inserted and tested for leak prevention.

Step 4: Delivery

Each pouch undergoes pressure testing and is packed with care for safe shipment to your facility or co-packer.

Pouch With Tap Manufacturing

Tap pouches require high-barrier films, advanced welding, and accurate fitting for secure dispensing.

- Lamination & Film Bonding – Layers are selected for strength, oxygen/light resistance, and liquid safety.

- Tap Housing Pre-Insertion – Molded tap or valve seats are welded onto pouches prior to final seal.

- Artwork Printing – Printed using rotogravure or digital printing for clean visuals.

- Leak Testing & QC – Each tap pouch is tested for pressure retention, flow rate, and sealing accuracy.

Value-added Services

Enhance logistics, branding, and usage with premium services supporting B2B buyers.

Filling Equipment Matching

Tap position and pouch specs are aligned to your filling and capping machinery.

Tap Options Library

Choose from 10+ tested tap models to suit your product’s viscosity and user environment.

Packaging Design Assistance

We help you build display-ready outer cartons and co-branded sleeves.

Bulk Liquid Logistic Consulting

We guide you on how to replace drums or jugs with tap pouches to cut cost.

What our happy customers say

Customer reviews are always the best reflection of our products and services. Take a look at what our customers have said.

“GreenWing’s Tap Pouches are strong, clean to dispense, and save us big on freight. Perfect for our 5L juice line.”

Michael Reeves

Logistics Manager

“Our refill pouches with tap have been a game changer. Beautiful print, no leaks, and GreenWing made setup easy.”

Sarah Nolan

Brand Owner

“We switched to tap pouches for industrial liquids—big improvement over rigid drums. Reliable supplier and excellent support.”

Jason Wang

Procurement Officer

Frequently Asked Questions

Q: What tap types are available?

A: We offer push taps, twist taps, and lock valves compatible with liquids of different viscosity.

Q: Can you help match the pouch to our filling line?

A: Yes, we design pouches and tap positions to match your filling and capping setup.

Q: Are tap pouches reusable?

A: Yes, many models are refillable and reusable, ideal for eco-conscious consumers or refill stations.

Q: Can I add a handle or hang hole?

A: Absolutely. We can add die-cut handles, hang holes, or reinforced top seals for hanging displays.

Q: What sizes are available?

A: Standard sizes range from 1L to 10L+, and custom sizes are available upon request.

Q: Are these pouches suitable for hot-fill or pasteurization?

A: Yes, with proper film selection, we support hot-fill and post-fill pasteurization requirements.