Retort Pouch Manufacturer

Wholesale Custom Retort Pouch Packaging

Retort pouches are heat-resistant, multilayer laminated bags designed for sterilized food packaging. They combine the durability of cans with the lightweight convenience of flexible packaging. Retort pouches extend shelf life, preserve flavor, and reduce storage and shipping costs compared to metal cans or glass jars.

Hot Retort Pouch

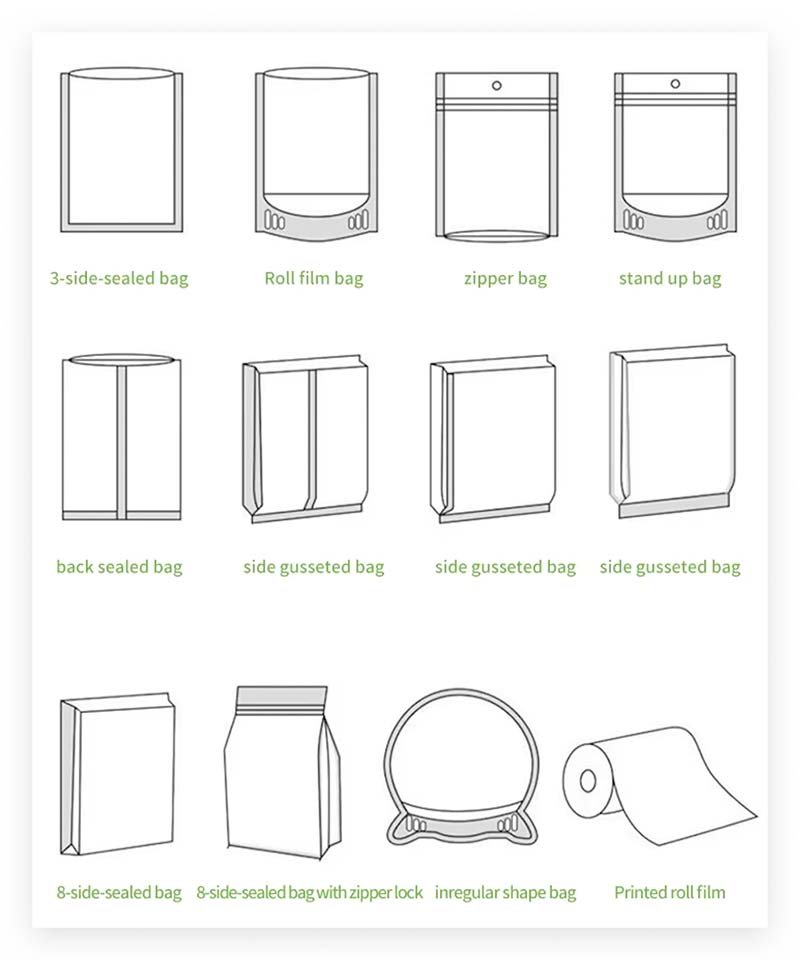

Retort Pouch Types

Retort pouches are available in different structures and designs to suit various food applications.

- Three-Side Seal Retort Pouch

- Stand Up Retort Pouch

- Gusseted Retort Pouch

- Spouted Retort Pouch

- Aluminum Foil Retort Pouch

- Transparent Retort Pouch

- Vacuum Retort Pouch

- Easy-Open Retort Pouch with Tear Notch

- Zipper Retort Pouch (resealable)

- Eco-Friendly Retort Pouch (recyclable films)

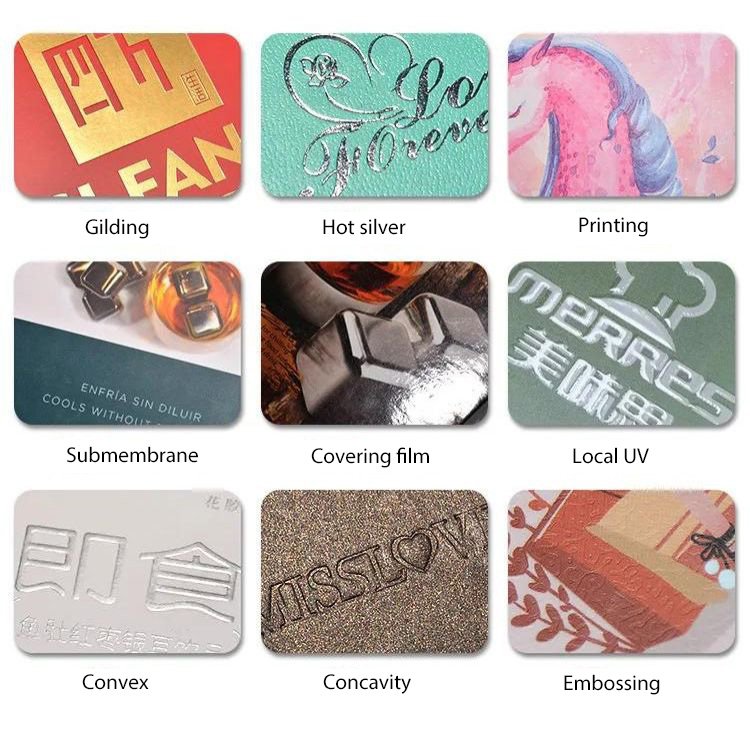

Retort Pouch Customization

Retort pouches can be tailored for product safety, shelf appeal, and convenience.

Small single-serve packs to large family-size pouches.

PET/AL/NY/CPP or recyclable high-barrier laminations.

Gravure/flexo printing up to 10 colors with glossy, matte, or metallic effects.

Spouts, tear notches, hang holes, and resealable zippers.

Still not find what you're looking for? Contact our consultants for more available products.

How to Customize Retort Pouch

Step 1: Consultation

Share your food product details and sterilization needs. We recommend suitable retort pouch materials and designs.

Step 2: Design

Upload your artwork or request design support. We provide mockups to visualize the final retort pouch.

Step 3: Manufacturing

Production includes lamination, printing, pouch forming, and sealing. Every retort pouch undergoes strict quality checks.

Step 4: Delivery

Pouches are packaged securely and shipped worldwide, with flexible logistics options to match your schedule.

Retort Pouch Manufacturing

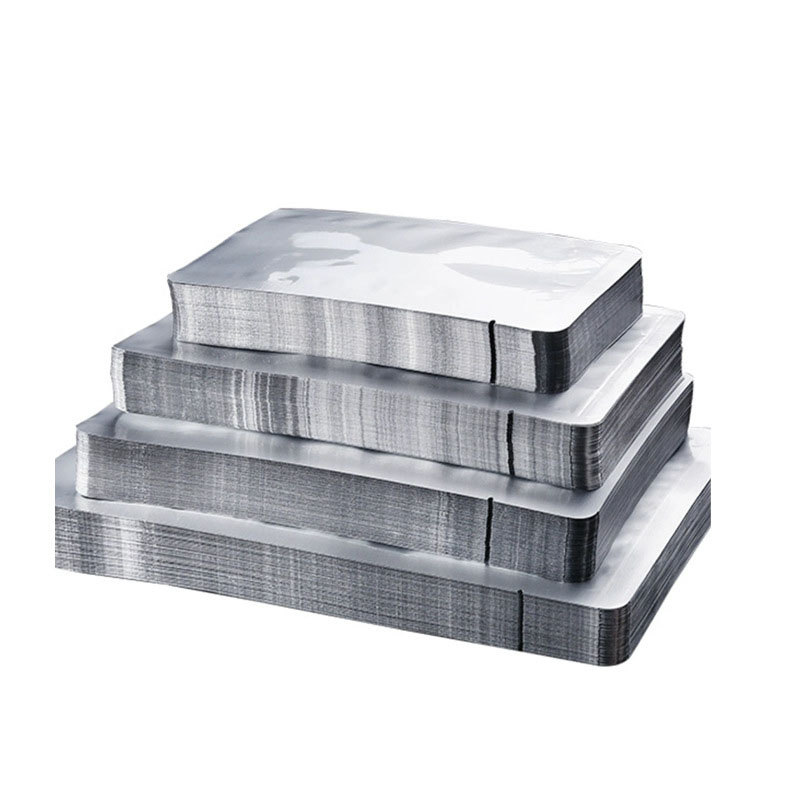

Retort pouch manufacturing requires advanced material handling and sterilization compatibility.

- Film Lamination – Multiple barrier films laminated for heat resistance and oxygen protection.

- Printing – High-definition gravure/flexo printing for branding and product info.

- Pouch Forming & Sealing – Automated machines form and seal pouches with precision.

- Sterilization Testing – Pouches tested for durability under high-temperature retort conditions.

Value-added Services

Our services ensure your retort pouches not only meet safety standards but also enhance brand value.

Filling & Sealing Guidance

Technical advice on retort filling machines.

Regulatory Support

Compliance with FDA, EU, and international food safety standards.

Sustainability Options

Recyclable retort pouch materials for eco-friendly brands.

Market Consultation

Assistance with positioning your ready-to-eat products in retail.

What our happy customers say

Customer reviews are always the best reflection of our products and services. Take a look at what our customers have said.

“Our ready-to-eat meals needed durable and attractive packaging. GreenWing’s retort pouches kept our food fresh, safe, and appealing to customers.”

Anna Williams

Product Manager

“Seafood requires strict safety packaging. GreenWing delivered top-quality retort pouches that withstand sterilization without compromising taste.”

Carlos Gomez

Operations Head

“The retort pouches from GreenWing gave us peace of mind. They are BPA-free, food-grade, and reliable for baby nutrition products.”

Mei Lin

Operations Director

Frequently Asked Questions

Q: What temperatures can retort pouches withstand?

A: They can handle up to 121–135°C during sterilization without compromising quality.

Q: Are retort pouches safe for baby food and pet food?

A: Yes, they are made from BPA-free, food-grade certified materials.

Q: How long is the shelf life of products in retort pouches?

A: Depending on contents, shelf life can be 12–24 months without refrigeration.

Q: Can retort pouches replace cans and jars?

A: Yes, they are lighter, cheaper to transport, and more eco-friendly while offering similar protection.

Q: Do you provide recyclable or eco-friendly retort pouches?

A: Yes, we offer recyclable high-barrier films for sustainable brands.

Q: What is the lead time for production?

A: Standard lead time is 20–25 days plus shipping, depending on customization.