Laminating Pouch Manufacturer

Customized Laminating Pouch Wholesale

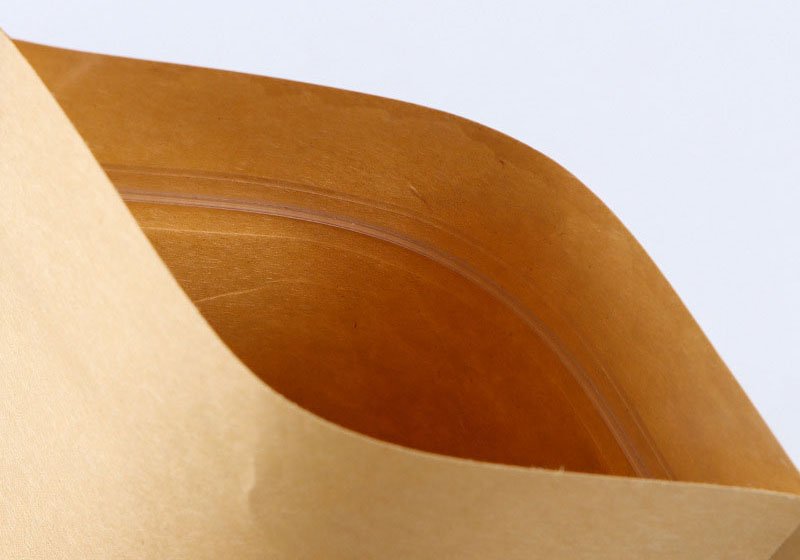

Laminating pouches provide premium protection with high-barrier, multi-layer films—ideal for preserving quality in powdered, liquid, or perishable goods. Durable, printable, and cost-effective compared to rigid cans or bottles.

Hot Laminating Pouch

Laminating Pouch Types

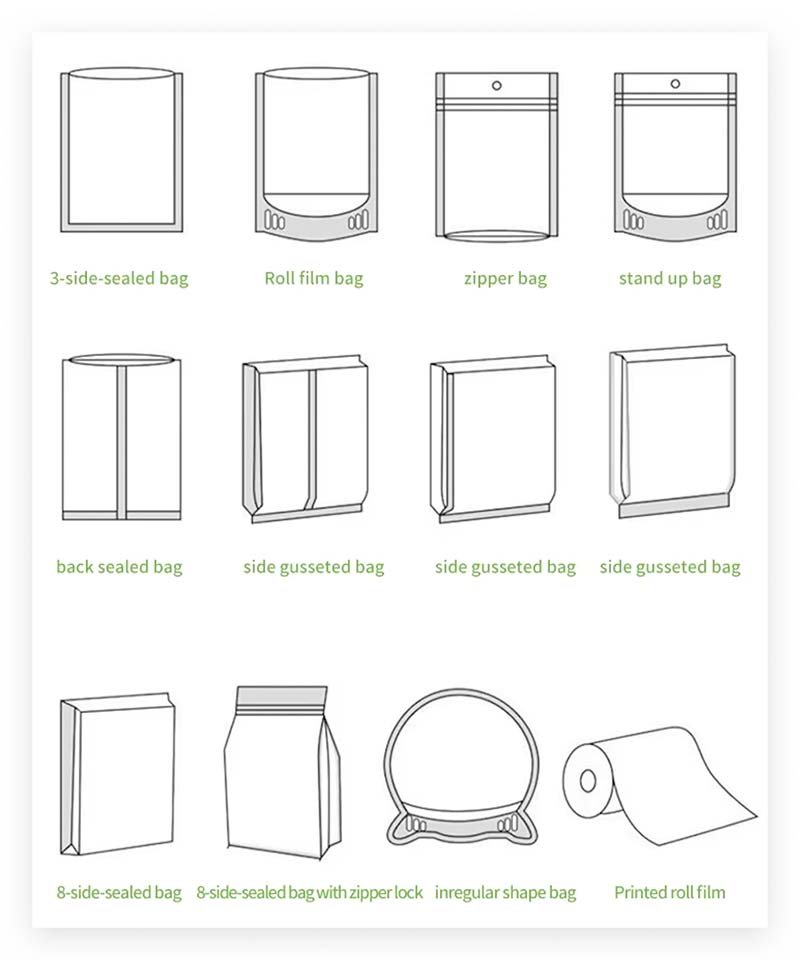

Laminating pouches come in versatile film combinations and structures to suit different packaging needs.

- Two-Ply Laminating Pouch

- Three-Ply Laminating Pouch

- Four-Ply Laminating Pouch

- Pre-made Laminating Pouch

- Heat-Seal Laminating Pouch

- L-Lock Base Laminating Pouch

- Spout Laminating Pouch

- Zipper Laminating Pouch

- Gusseted Laminating Pouch

- High-Barrier Foil Laminating Pouch

Laminating Pouch Customization

Tailor laminating pouches to product needs, shelf appeal, and functional design for optimal performance.

Choose the exact dimensions and bag style, whether flat, square-bottom, or gusseted for extra capacity.

Adjust film thickness to ensure puncture resistance and product weight support.

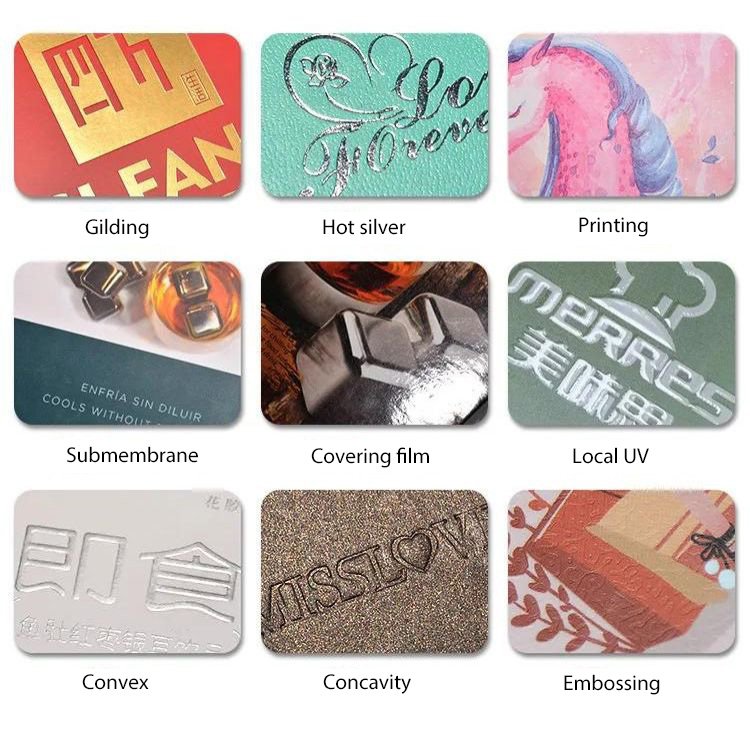

Full-color printing with gloss, matte, or metallic effects for standout packaging.

Pick stand-up, gusset, or flat styles; add spout or zipper for usability.

Still not find what you're looking for? Contact our consultants for more available products.

How to Customize Laminating Pouch

Step 1: Consultation

Share product type, barrier needs, and volume goals—we’ll recommend the right laminating structure for your Laminating Pouch.

Step 2: Design

We craft digital mockups and technical layouts, integrating multi-layer film requirements and branding elements.

Step 3: Manufacturing

Advanced lamination, precise printing, and pouch forming begin once approved—producing your Laminating Pouches at scale.

Step 4: Delivery

Completed pouches go through QC, are securely packed, and shipped globally with full logistics support.

Laminating Pouch Manufacturing

Laminating pouch production ensures durable, high-barrier packaging through layered bonding and exact sealing.

- Layer Lamination – Films are heat-coated and combined under pressure for optimal barrier function.

- Printing & Drying – High-definition printing follows lamination, then films improve adhesion via drying.

- Pouch Converting – Laminate is cut and sealed into styles such as stand-up or flat pouches.

- Functional Attachment – Features like zippers, spouts, or tear notches are added, finalized by QC leak testing.

Value-added Services

Enhance the value of your Laminating Pouch with strategic services for production efficiency and market success.

Barrier Testing Reports

Receive lab data on oxygen/moisture resistance to validate shelf-life claims.

Film Compatibility Testing

Ensure pouch structure works with your filling equipment through prototype trials.

Regulatory Consulting

Guidance on FDA, EU, or other compliance related to laminate materials.

Custom Fulfillment Options

Bundling, kitting, or private-label repackaging to streamline your logistics.

What our happy customers say

Customer reviews are always the best reflection of our products and services. Take a look at what our customers have said.

“GreenWing’s Laminating Pouches kept our industrial powders safe in transit. The barrier quality and durability are outstanding.”

Bruce Adams

Purchasing Manager

“Excellent lamination quality and vivid printing. These pouches boosted our brand image and ensured freshness for premium supplements.”

Olivia Sutton

Food Safety Lead

“The team delivered perfect prototypes, excellent barrier performance, and smooth delivery. GreenWing is a reliable packaging partner.”

Ethan White

Operations Director

Frequently Asked Questions

Q: What laminate structures are available?

A: We offer 2–4 layer options combining PET, foil, nylon, and PE for specific barrier needs.

Q: Can you provide heat-seal only pouches?

A: Yes, heat-seal laminating pouches without zippers or spouts are available for simplicity and cost-efficiency.

Q: Do you test for barrier performance?

A: Yes, we can supply oxygen & moisture transmission rate (OTR/MTR) reports to confirm shelf-life performance.

Q: Can we get small sample runs?

A: Certainly, we support sample orders of 1,000–5,000 pieces for testing before committing to larger batches.

Q: Are you able to laminate printable films?

A: Yes, we use printable PET or BOPP films to achieve high-resolution branding in laminates.

Q: Do you support co-packing or kitting?

A: Yes, we offer customized packaging services like co-packing and kitting to support end-to-end supply solutions.